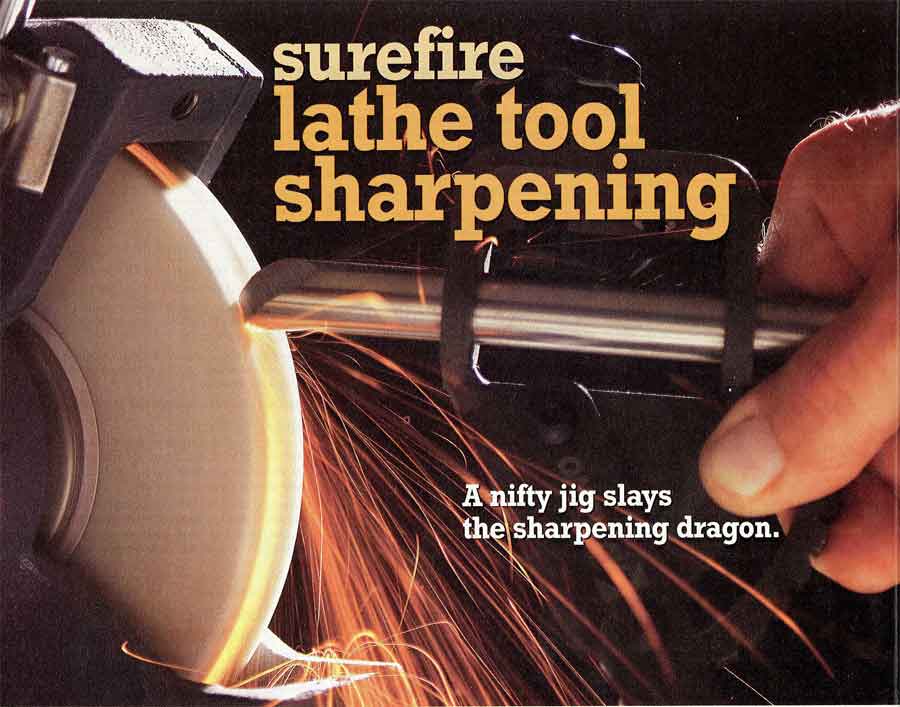

Next, we asked our pros how to put the Wolverine Jig to best use. Here's what they showed us.

First, let's get familiar with the jig

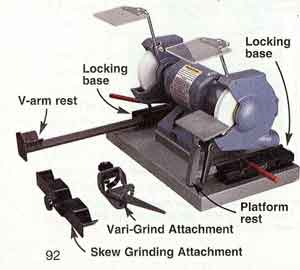

The complete sharpening system,

shown left, includes the Wolverine

Grinding Jig, consisting of two locking

bases, a V-arm rest, and an adjustable

platform rest (about $80), and two

accessories: the Vari-Grind Attachment

(about $48) and Skew Grinding

Attachment (about $27).

Use the V-arm rest by itself to sharpen your roughing gouge and parting tool. It also supports the Vari-Grind Attachment, used for putting the popular side grind on bowl gouges and fingernail grind on spindle gouges. To sharpen your

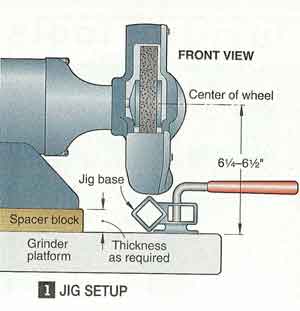

Adjustable locking bases secure the rests for proper tool positioning. This also allows you to grind on either wheel with both rests. The bases mount directly under the grinding wheels, as shown on Drawing 1, so make sure your grinder accommodates them. To elevate the center of the grinding wheels to the height shown, insert a spacer block between the grinder and its platform.

You may find the prospect of spending $160 for a jig to sharpen your lathe tools daunting. That's about the cost of five mid-priced M2 high-speed steel tools. But if they're not sharpened properly, even the most expensive tools aren't much good. The Wolverine Jig allows

SHOP TIP

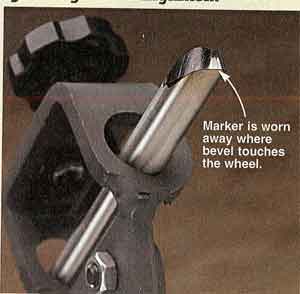

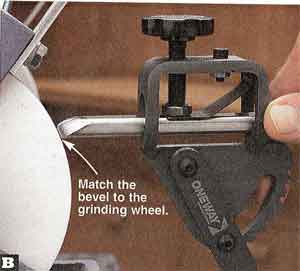

How to ensure perfect tool-to-grinding-wheel alignment

Blacken the bevel of the tool with a permanent felt-tip marker. Adjust the tool rest, and align the tool's bevel with the wheel by sight. Switch on the grinder, and barely touch the tool's bevel to the wheel. In the photo, right, the shiny spot shows that the bevel's heel contacted the wheel first. Readjust the tool rest so the wheel removes the marker all the way from the bevel's heel to the cutting edge.

What you need to know about grinders and wheels

Most general-purpose grinders run at 3,450 rpm and come equipped with gray utility wheels. This combination of high speed and hard wheels easily overheats lathe tools, leading to short edge life. Our experts recommend an 8" slow-speed grinder (1,725-2,000 rpm) equipped with white aluminum oxide wheels. These wheels are designed to wear away during sharpening, constantly exposing new cutting particles. This results in cooler, more efficient grinding. Fit your grinder with one 60-grit wheel for rough shaping your tool profiles when needed, and one 100-grit wheel for routine sharpening.

If you already have a 3,450-rpm grinder you don't have to replace it; fit-, ting it with white aluminum oxide wheels is more important than slow speed. Also, a 6" grinder is acceptable, but no matter which size grinder you use, replace the wheels when they wear down to about 5" in diameter.

You'll need to keep the wheels dressed to remove metal particles and maintain flat surfaces. Oneway offers the Wolverine Dressing Jig (about $65), and most woodworking and turning supply catalogs offer inexpensive diamond wheel dressers ($16 to $40).

For best results, use light grinding pressure, and move the tool from side-to-side to avoid wearing furrows in the wheels. For safe operation when using the V-arm rest, keep the tool's contact point well above the grinding wheel's centerline. When using the platform

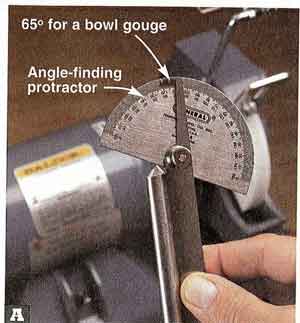

Setting up the jig

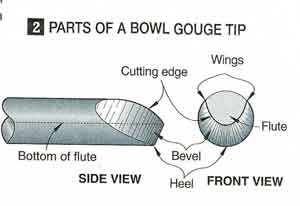

Note: Drawing 2 shows the various parts of a bowl gouge tip. Although the geometry of spindle and roughing gouges is different, the parts have the same names. Adjusting the Wolverine Jig to help you grind the angles described in the next section is easy. First, set an angle-finding protractor to the desired angle, and compare the tool's existing bevel to it, as shown in Photo A. This helps you form a mental picture of where to grind away metal. Then position the tool in the appropriate rest with its bevel contacting the grinding wheel. Adjust the rest to grind the bevel to the desired angle, and grind just enough to start forming a bevel. Check the angle with ' the protractor, and adjust the rest as necessary. With a couple of tries, you'll be right on the mark.

How to sharpen 6 basic turning tools

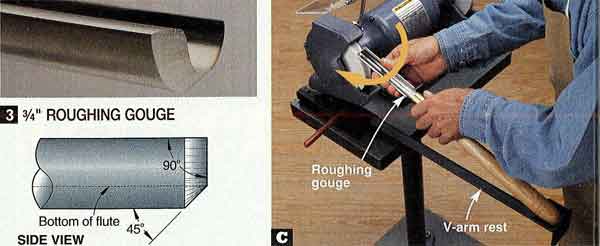

Position your roughing gouge with the end of its handle in the V-arm rest and its bevel on the grinding wheel. Adjust the V-arm to grind a 45° bevel, where shown on Drawing 3. Touch the roughing gouge's bevel to the wheel starting at the wing on one side of the flute. Roll the bevel across the grinding wheel all the way to the opposite wing in a continuous motion, as shown in Photo Ñ Maintain the 90° tip shown on the drawing.

Bowl and spindle gouges come from the factory with a variety of grinds, some with limited uses and others not usable at all until they are reground. With more cutting edge and less chance of catching, a side grind on these gouges is becoming very popular. (In a side grind, the bevel extends back from the tip along the tool's side, in contrast to the "straight around" bevel on a roughing gouge.) Because of the wide range of motion required, this grind takes a lot of practice to execute freehand. Fortunately, the Van-Grind Attachment for the Wolverine Jig makes it possible with little practice.

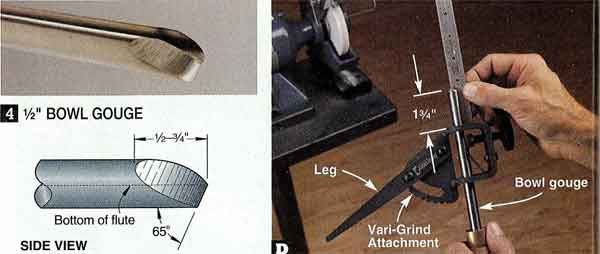

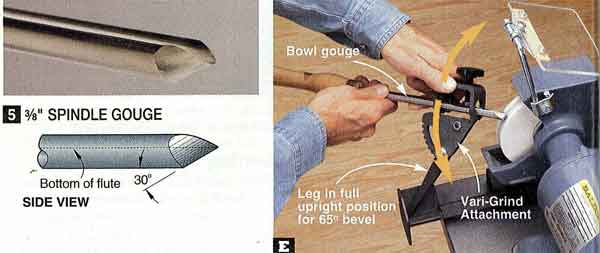

To sharpen bowl and spindle gouges, clamp the tool in the Vari-Grind Attachment with PA" protruding, as shown in Photo D. Place the attachment's leg in the V-arm rest, and touch the tool's tip to the wheel. Adjust the rest and the angle of the leg to grind the bevels shown on Drawings 4 and 5. With the grinder off, touch the tool's bevel to the wheel, and practice moving the tool from side to side to get comfortable with the motion needed to successfully sharpen your gouges. Now switch on the grinder, and gently touch the tool to the wheel, rolling it from side to side, as shown in Photos E and F.

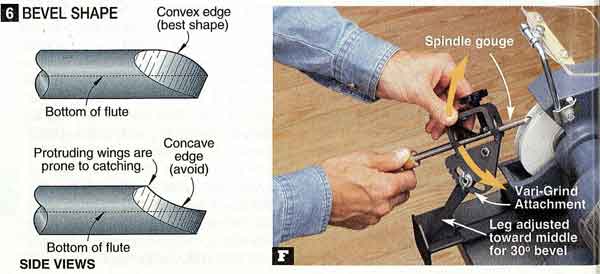

Roll the bowl gouge far enough to each side to grind the flute's wings back about 1/2-3/4" from the tool's tip, as shown on the drawing. Examine the bevel from the side. Look for a smooth, slightly convex profile, shown on Drawing 6. A slightly concave profile leaves the flute's wings protruding beyond the center of the cutting edge, making the gouge prone to catching in your work. Correct a concave profile by removing more material from the wings and the heel.