Machining Wood

My dictionary defines "technology" as "applied science; systematic knowledge of the industrial arts." The implication for the woodworker is that while much practical knowledge can be gained by studying the basic science of wood (as we have been doing up to now), much also can be gained by investigating modern industrial practices. Far more is learned through solving the daily problems of production woodworking than any individual craftsman could hope to accumulate in a lifetime of custom handcrafting.

ll is convenient to analyze machining as the action of a culting tool on

a piece of wood or workpiece, with the cutting action that takes place

referred to as chip formation, wherein a portion of wood called the chip

is separated from the workpiece. Chip formation involves the geometry of

the tool, the condition of the wood and the motion of the tool relative

to the orientation of the structure of the wood.

The objective of machining always should be the paramount consideration.

The approaches used may differ drastically, depending on the objectives

sought. These objectives may he classified as:

Severing: To make two or more pieces from one, for example, splitting

firewood or bandsaw-ing rough parts from a plank.

Shaping: To impart a specific shape to the workpiece, in some cases a

flat-planed surface,

in some cases a flat-planed surface, in other some specific contour.

Joining a

flat surface on a cupped board is one example,

millng an ogee molding is another .

Surfacing: To create a surface of prescribed quality, for

example, sanding a surface prior to finishing, or jointing edges that

are suitable for gluing.

In most cases, two or even all three of the above are involved

concurrently. In ripping boards into strips, for example, one might want

the resulting surface to be true enough and of appropriate condition to

be glued. In most machining the objective is the workpiece, and the

nature of the chip removed is irrelevant. An interesting exception is

knife-cut veneer, where the chip itself, the veneer, is of primary

interest, and the surface left on the workpiece becomes one face of the

veneer that will be removed by the next cut. Although the average

woodworker is not involved in making veneer, the user of veneer should

understand the machining process involved

Let's survey the interrelationship of the workpiece, the tool and the

chip formation in machining.

The workpiece

The aspects of wood that affect machining have already

nature of wood in terms of its three-dimensional properties is

particularly important. Density variation among and within species is

also of obvious importance, as is unevenness of grain, especially in

ring-porous hardwoods and uneven-grained softwoods. Heartwood

extractives in some species are particularly abrasive and contribute to

tool dulling. Defects such as knots create both irregularities of grain

direction and variations in density. Structural irregularities such as

wavy or interlocked grain cause special machining problems. Moisture

content influences machining as. it affects the strength of wood, and so

do stresses or checks developed in drying.

Strength of wood is, of course, the bottom line. The relationship

between the strength ol wood parallel to the grain and perpendicular to

the grain is perhaps the most important part, although every other

factor affecting strength in turn affects machining.

The tool

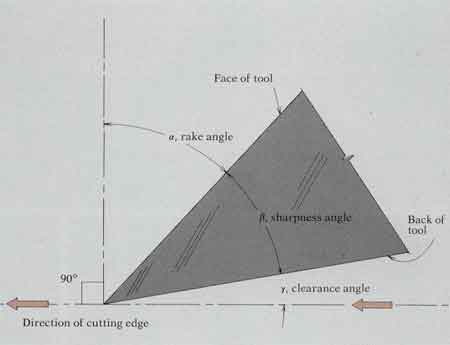

At the business end of a cutting tool, where chips are being formed, the

tool geometry can be described in terms of a cutting edge formed by its

intersecting face and back surfaces, or planes (1). The critical

geometry of the cutting edge is usually defined in terms of its

direction of motion:

î = the rake angle [also called the cutting angle, the hook angle, the

chip angle and the angle of attack) is the angle between the tool face

and a line perpendicular to the direction of travel of the edge. /3 =

the sharpness angle, the angle between the face

and back of the knife.

ó = the clearance angle, the angle between the back of the knife and the

direction of travel of the edge. As required by circumstance,

cutting-tool geometry can be varied considerably. The sharpness angle

will always be a positive value. The cutting angle and clearance angle

can be negative values. In the case of the

between tool and workpiece.

| 1—The business end of a culling tool consists of an edge formed by

ils intersecting face and back surfaces. Its geometry can be described

by the rake angle, î (alpha), measured from a line perpendicular to the

direction of travel to the tool face; the sharpness angle, p (beta),

measured between the face and back of the lool; and the clearance angle,

ó (gamma), measured between the hack of the knife and its direclion of

travel. |

|

Chip formation

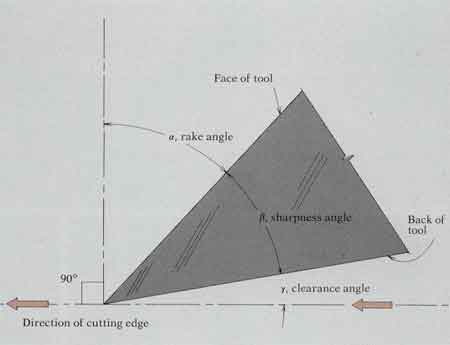

| 2—Cutting action idealized. Energy Is consumed in severing the wood

to form the chip, in deforming or rotating the chip, and in friction of

the tool face against the chip, plus friction of the tool back against

the new surface of the workpiece. |

|

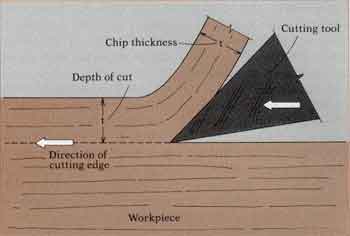

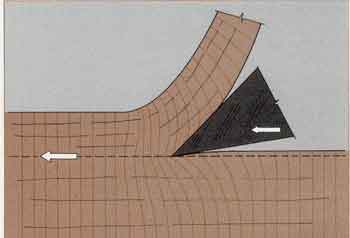

| 3—Cutting action in reality. The wood does not fail until ultimate

stress is reached, and stress is always accompanied by strain. As the

cut proceeds, the workpiece deforms ahead of the tool, severs, and then

both workpiece and chip spring back to some extent. |

|

Types of cutting action

There are two basic types of cutting action. The first is called

orthogonal cutting, in which the tool edge is more or less perpendicular

to its direction of motion and where the cut is in a plane parallel to

the original surface of the workpiece, with removal of a continuous

chip. An ordinary plane peeling a shaving from the edge of a board is

one example. The second type is referred to as peripheral milling, in

which a rotary cutterhead carrying one or more cutting edges

intermittently contacts the work surface. Each cutter proceeds on a

curved path, and removes a single chip. Virtually every cutting

situation can be compared to either orthogonal cutting or peripheral

milling. Note that as the cutter-head radius increases in peripheral

milling, it approaches orthogonal culling.

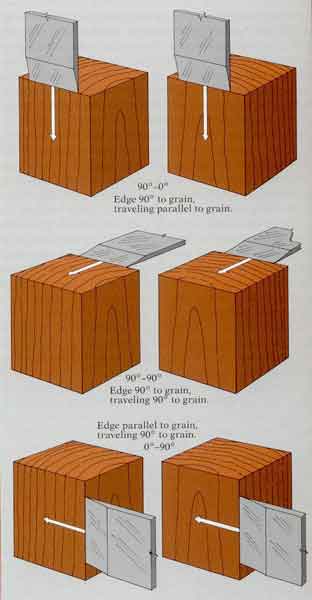

Visualize a cube of wood with its sides oriented in the radial,

tangential and longitudinal planes. According to notation reported by

W.M. McKenzie, orthogonal cutting is described by two numbers. The first

is the angle between the cutting edge and the cellular grain direction

and the second the angle between direection of cutting and the grain

direction. Thus there are three basic cutting directions: 90°-0°

cutting, 90°-90° culling and 0°-90° cutting (!). By considering each

type of orthogonal

cutting, some common types of machining can be

understood more clearly.

|

| 1—The three types of orthogonal culling. The first number is the angle between cutting edge and grain direction; the second is the angle between direction of cutting and grain direction. |

90°-0° cutting (planing along the grain)

Parallel-to-grain culling is best typified by the standard hand plane.

The chip forms as the plane is pushed along the board. The typical

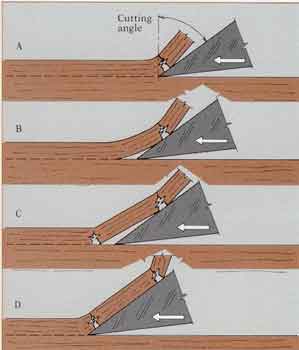

cutting action involves a cyclic sequence of events (2), The iron

separales fibers lengthwise to begin a chip (A). As the knife advances,

the separated chip slides up the iron. The chip is now a cantilever beam

that resists bending. It lengthens itself by failure of the wood in

tension perpendicular to the grain well ahead of the knife edge (B).

Finally, the chip is so long that bending stresses equal the strength of

the wood and the chip breaks (C). The iron advances to the fracture

point and begins to lift ihe next segment of chip (D) and so on. The

chip, produced in a long jointed curl (see Figure /, page 144), is

referred to as a Type I chip in 90°-0° cutting.

The typical plane cutter or iron is set al an angle of 45°. Sharpening

to an angle of 30° leaves a 15° clearance angle. If the rake angle

becomes too great, the friction of the chip upon the iron face would

increase and Ihe efficient bending and breaking action would be lost-

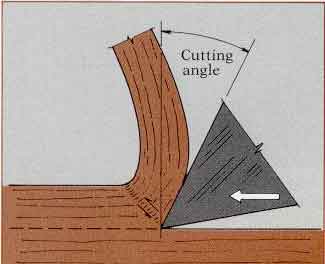

ward compression and ii smaller component of upward lifting are

transmitted to ihe chip. Failure may occur as a diagonal plane of shear,

bending the fiber structure, so curl of deformed cell structure. This is

classified as a Type II chip (3). The cutting edge produces the surface

as it dislodges cell structure. Greater force is required because of the

compression resistance. Where the tool is well controlled and a

reasonably thin chip is taken, chip formation takes place quite

uniformly and an excellent surface is produced. Some special hand planes

with a cutting angle of only about 30° are designed to take

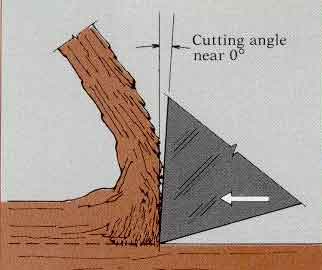

As small (or even negative) cutting angles are used, the grain. The

knife edge produces the surface as it shears free the cell structure. As

the wood fails in compression, the damaged cell structure packs up

against the cutting face and may form a wedge that transmits force and

causes failure out ahead of the knife edge, often below the projected

cutting plane. The failure is erratic and leaves an irregular surface,

and is accompanied by an irregular chip of mangled cell structure. This

is Type III chip formation (4). With very low cutting angles, a smooth

surface and uniformcutting action occur only when a thin enough chip is

taken to form Type II chips. This is the cutting action of scrapers.

|

|

2—The cutting action in planing wood. The cut begins at A. The chip

bends as it slides up the knife, and the wood fails ahead of the edge

due to tension perpendicular to the grain, B. Finally the chip breaks, Ñ

whereupon the next segment of the cut starts, D. In 90°-0° cutting this

is known as a Type I chip, produced by a relatively large cutting angle. |

| 3—At small cutting angles, the face of the knife produces more forward compression than upward lifting. Failure occurs as a diagonal plane of shear right At the cutting edge. With, enough force and a thin chip, the workpiece surface can be left in excellent condition. This is a Type II chip in 90-0" cutting. |

|

|

4—At very small (or even negative) cutting angles, force is transmitted mainly as compression parallel to the grain. The damaged cells pack up against the culling face, often causing erratic failure ahead of and below the edge. This is a Type III chip in 90°-0° cutling. The snowplow effect can only be avoided by taking a very thin chip, whereupon it becomes Type II cutting. Cabinet scrapers work this way. |

|

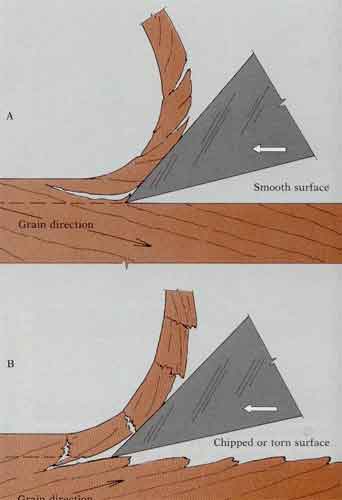

The quality of cutting depends mainly on two factors: the grain direction and the mechanics of chip breakage.

Figure 2 on page 147 assumes perfectly straight grain, which in reality is more the exception than the rule.

Usually some degree of cross grain exists wherein the fiber direction either rises ahead of the projected line

of cut or leads down below it. The former case is termed cutting with the grain, the latter cutting against the grain (I),

Cutting with the grain is preferable, since the splitting of the wood associated with chip formation projects harmlessly into

the next chip segment which subsequently will be removed. The cut produces a new surface generated by the continuous severance

at the tool edge. Culting with the grain is very efficient because most of the chip segments fail readily due to cross grain.

The woodcarver will find that cutting with the grain at an acute angle to the grain is a fairly efficient way to remove large

amounts of slock. At the same time, 90°-0° Type I chip formation using a hand chisel can be painfully undesirable in carving.

The case in point involves carving with the grain, where a splinter-type

chip slides all the way up the face of the tool and jabs the carver in the

hand (2). I have numerous scars on the outside heel of my left hand thanks

to this situation. I collect another scar every time I fail to wear a glove

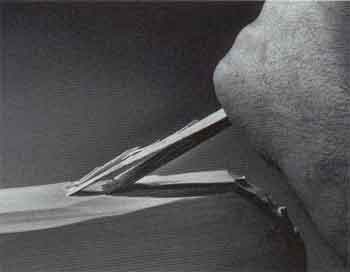

By contrast, cutting against ihe grain can result in chip formation where

the splitting projects below the intended plane of cutting. The resulting

surface is called chipped or torn grain. In some cases, as in planing the

edge of a flatsawn board with spiral grain or in passing a flatsawn board

with diagonal grain through a surface planer, the board can be alternately

turned end-for-end so that culling will occur with the grain. In other cases,

however, as with the bulge of grain direction associated with a knot, some

cutting must take place against the grain. To minimize the depth of torn

grain, the breaking length of the chip segments must be controlled. One

approach is to take an extremely thin cut, in which the chip segments break

frequently. Otherwise, a "chipbreaker" must be introduced, such as the

cap iron on a hand plane (3). The cap must be located suitably close to the

cutting edge and must fit tightly enough to the face of the iron so the chip

will not lodge but will slide up easily and bend beyond its breaking point

quickly. The Face and mating edge of the cap should be shaped as precisely

as the cutting edge of the iron itself, for the ñað iron is an integral pan

of the cutting mechanism.

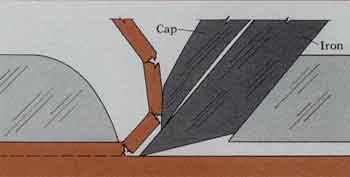

The importance of the clearance angle in the cutting process should be

appreciated. As with the "springback" of the wet sponge, it is also true

that some deflected cell structure will recover alter the chip lorms. In

order for the back of the cutting edge to clear this material, fric-tional

drag and pressure against the back of the knife must be eliminated. If the

cutter were infinitely sharp, of course, little clearance would be needed,

and recommended clearance angles of up to 15° may seem excessive. However,

such large clearance angles are probably safeguards against less-than-perfeel

sharpening. If the back (beveled side) of the cutter is not perfectly flat,

the clearance angle is reduced. As will be pointed out in discussing

sharpening, it is crucial that no portion of the cutter be deeper than the

cutting edge itself.

In 90°-0° cutting with a hand chisel, the back of the tool itself guides the

cutting direction. The clearance angle is effectively zero, and springback

is automatically compensated by the angle at which the tool is held.

Frictional resistance is overcome by whatever force is applied to advance

the chisel.

Most hand planes used along the grain involve 90°-0° cutting, whether they

operate on the whole surface of the wurkpiece (as in planing a flat surface)

or whether they plow a groove or form a rabbet. Spokeshaving down a canoe

paddle is another example of 90°-0° cut-ling where tool geometry and depth

of cut are fixed by tool design and adjustment. Rough-shaving an ax handle

with a drawknife and taking long shavings along the grain with a pocketknife

are also 90°-0° cutting; in these cases the cutting angle, clearance angle

and depth of cut are controlled by the way the tool is held.

|

|

|

1—In ihe real world, the wood grain is rarely parallel to the cutting

direction Usually ihe fibers are rising ahead of (he line of cut, and

cutting with the grain leaves a very smooth surface (A). When the Fibers

lead down below the line of cut, cutting against the grain leaves a chipped

surface (B). We usually reverse either the work or the tool, to go with the

grain. |

|

|

| 2—In woodcarving, ihe splinter-type chip resulting from 90-0° cutting with ihe grain can slide up the tool face and jab an unwary carver In the hand. |

|

3—In 90°-0° cutting with a hand plane, the cap Iron minimizes frorn grain by

breaking the chip near the cutting edge. |

|

Peripheral milling (machine planing)

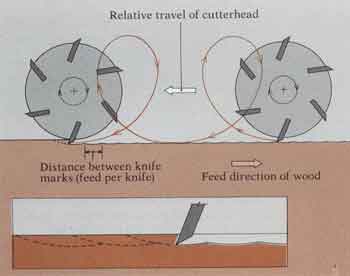

Orthogunal cutting in the 90°-0D mode has a counterpart in peripheral

milling in the cases of the typical jointer, single surfacer, spindle shaper

and router— wherever a revolving cutterhead operates along an edge or face

of a board.

The cutting action is modified by the path of each cutting edge, which by

combined revolution of the cutter-head along the surface of the workpiece

follows a trochoidal path (1/. Each cutting edge takes a curved chip from

the workpiece. Customarily, rotation of the cutterhead moves each knife in a

direction opposite ihe relative direction of the workpiece, representing the

up-milling condition (1, inset). In most rotary cutterhead designs the

cutting angle is decreased to between 10° and 30°. This requires more power,

but the chip type produced approaches a scraping Type II or Type III chip

rather than a splitting action, as in Type 1 chips, and there is less

uncontrolled splitting ahead of the knife edge. The surface generated by the

overlapping cutting arcs of successive edges is wave like. These waves are

often visible and are known as knife marks. Figured shows an extreme case of

knife marks in crudely planed structural lumber—only four to the inch. The

marring of the surface is plainly visible. However, in finish lumber the

best surfaces are produced by 12 to 25 knife marks per inch. In this case,

the height of the waves is typically quite small, and may not be seen easily

with the naked eye. Their visibility is the result of crushed or buckled

cells, rather than the actual surface irregularity of the waves (3). When

the number of knife marks per inch exceeds 30, unless the culling edges are

extremely sharp, the surface may actually get worse. The chip gels so small

that each cutting edge does not bite, but rather rides over the surface, as

with the table knife and ihe wet sponge. Frictional heat also may be

produced and the resulting surface, although apparently smooth,

|

|

|

|

1 In peripheral milling, each cutter actually follows a trochoidal path relative to the work piece, the result of culter-head rotation plus feed. Each cutter takes a curved chip from the workplece, usually by up-milling (inset). |

|

|

| 2—Crushed cells delineate knife marks—about fc.ur lo the inch—on this eastern hemlock board. |

3—Light reflection reveals closely spaced knife marks on this butternut board |