|

|

This elegant sleigh bed in cherry has turned crest rails. Rosettes top the splayed head and footboards

|

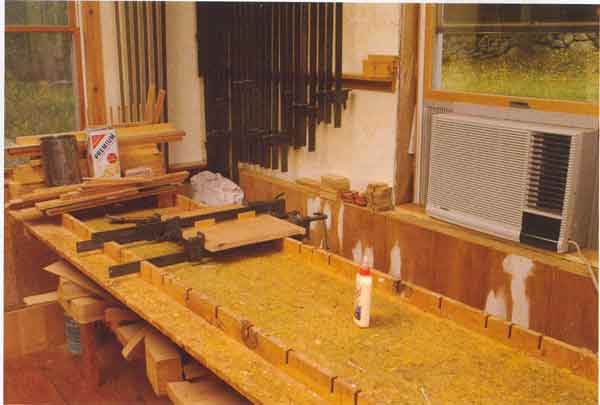

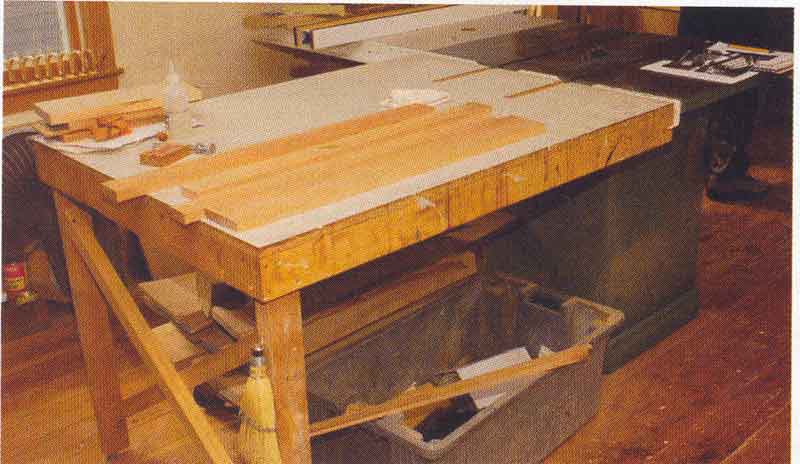

A bench in the corner is used for gluing

up. Note the slots in the wood rails

designed to accept the sash cramp bars

|

|

|

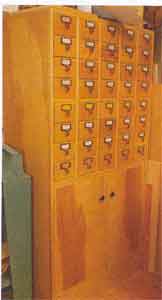

Chris salvaged these drawers from a local library and uses them for storage

|

Much of Chris furniture is inspired by the Shakers, evident in this cherry dining table

|

|

|

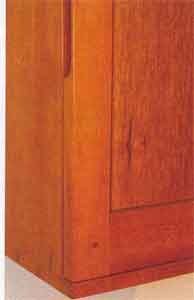

This cherry wall cabinet has textured door panels and smooth stiles and rails |

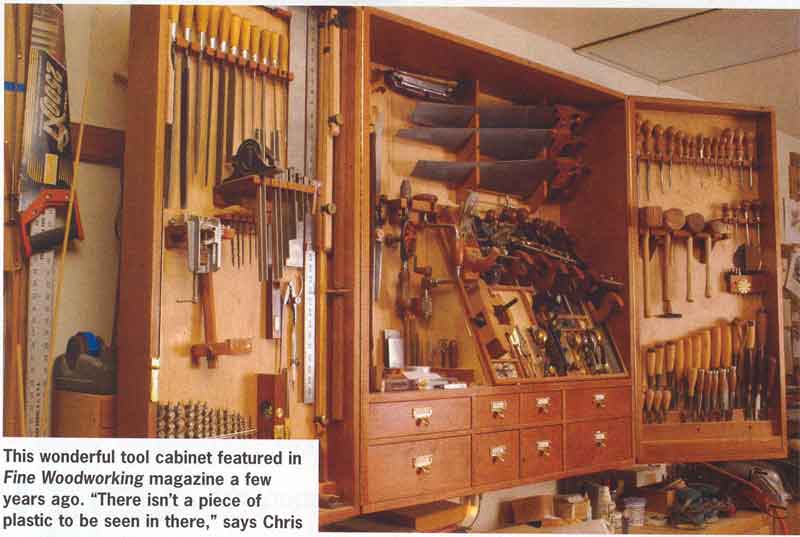

This wonderful tool cabinet featured Fine Woodworking magazine a few years ago. "There isn't a piece of plastic to be seen in there," says Chris |

| |

|

|

|

The sleigh was popular 100 years ago during the New England winters. This Snow Glider is made of laminated ash with brass metalwork. It's finished in lacquer with gold leaf pin stripes and leather upholstery

|

|

|

|

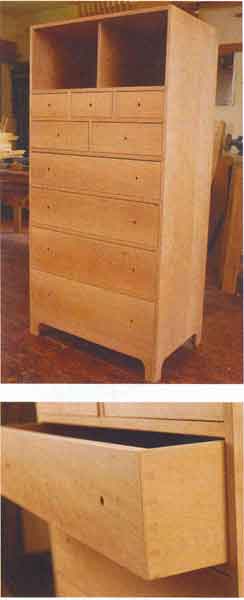

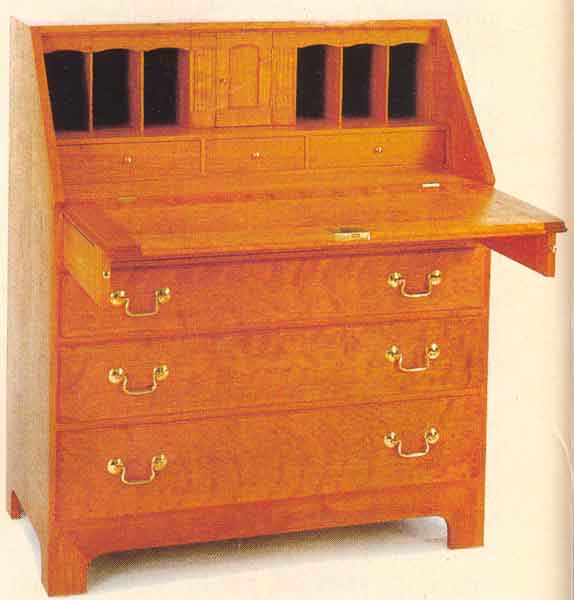

A cherry chest of drawers with around 200 hand-cut dovetails...

|

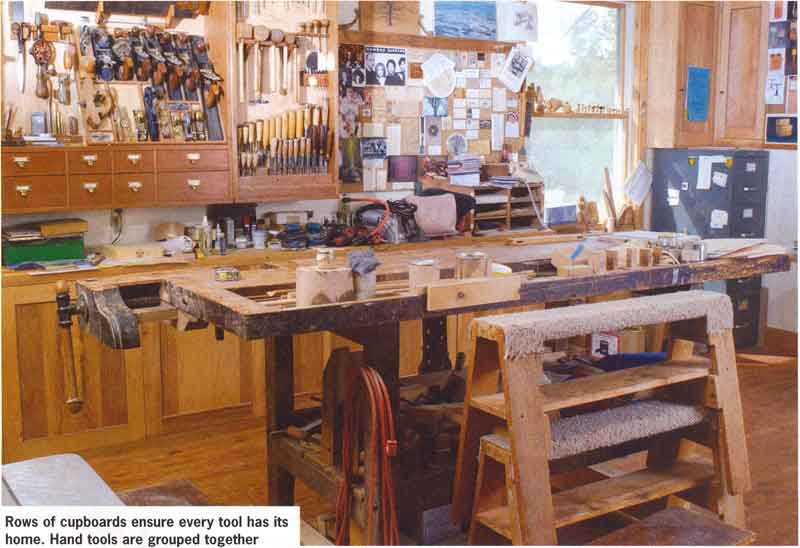

Rows of cupboards ensure every tool has its home. Hand tools are grouped together |

|

|

Powered sanders include an elderly Skil chain-driven model

|

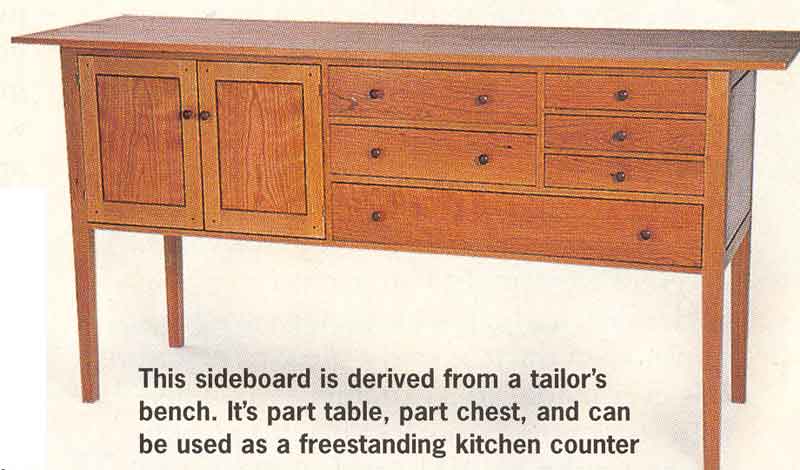

This sideboard is derived from a tailor's bench. It's part table, part chest, and can be used as a freestanding kitchen counter |

|

|

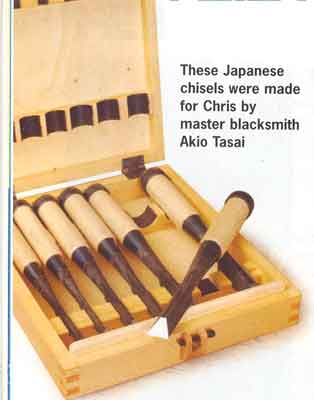

These Japanese chisels were made for Chris by master blacksmith Akio Tasai

|

An old chisel may well become a drawer handle for workshop storage |

|

|

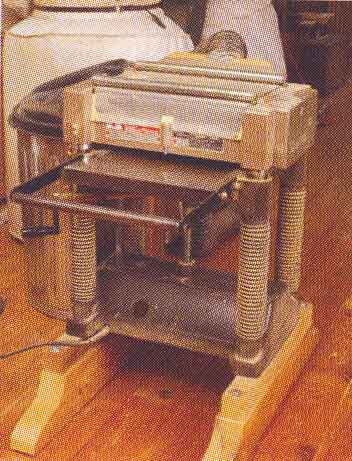

This Makita thickness planer copes with boards up to 15 " wide

|

Machining is centred around a cast iron General table saw, which Chris uses fitted with moulding cutters |

|

|

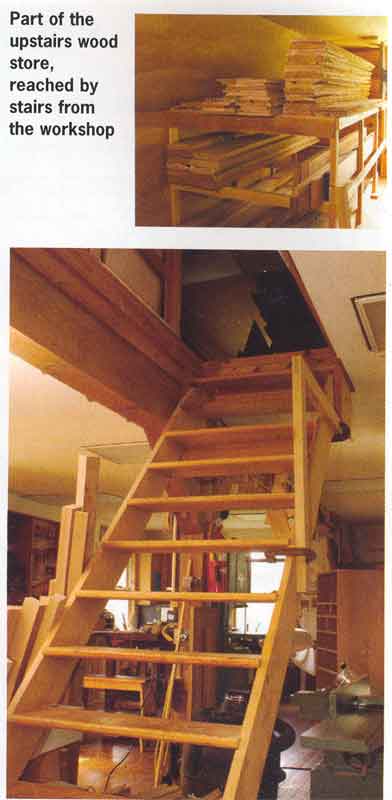

| Part of the upstairs wood store,

reached by stairs from the workshop |

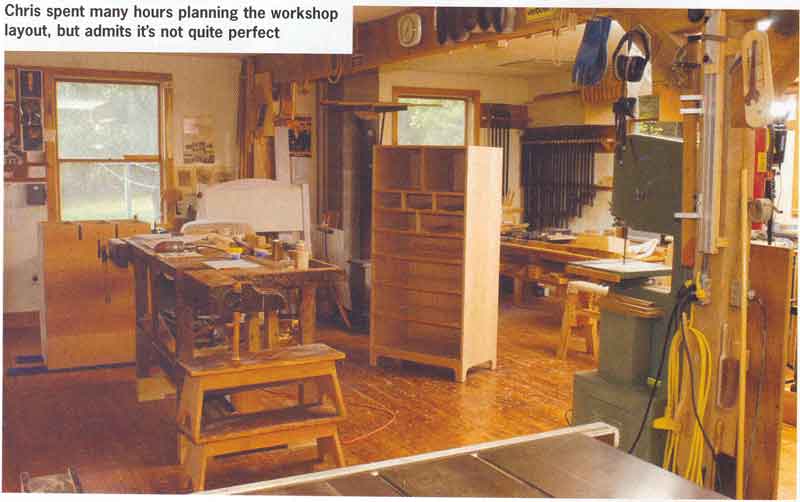

Chris spent many hours planning the workshop layout, but admits it's not quite perfect |

This stunning Slant-Top Desk in figured cherry has three secret compartments, a hidden silver dollar and 130 dovetails. It costs around $13,000...

|

|